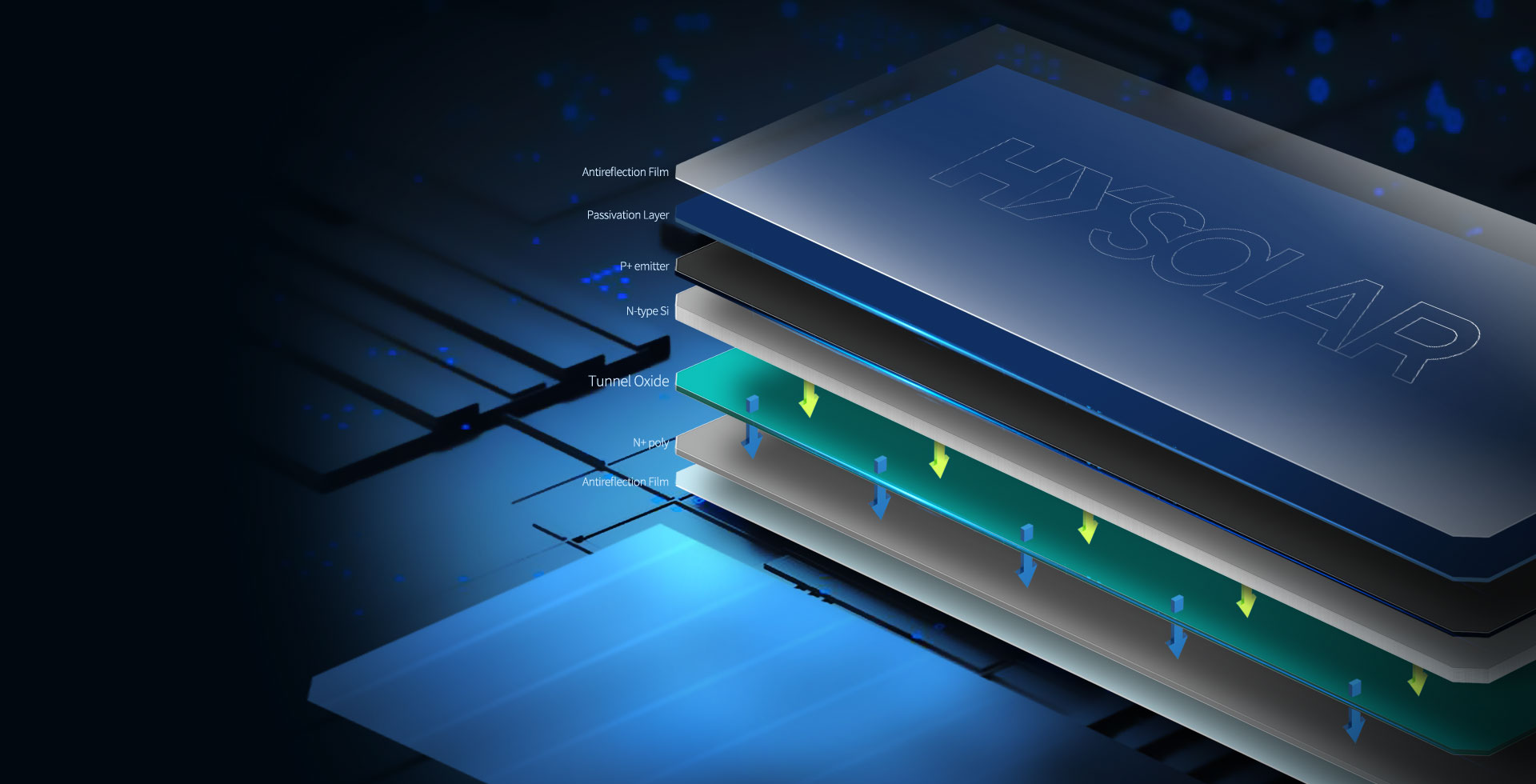

Plasma enhanced chemical vapor deposition

Plasma enhanced chemical vapor deposition

High-efficiency SE tech

High-efficiency SE tech

LECO Laser-Assisted Sintering

LECO Laser-Assisted Sintering

To improve Voc & Isc

To improve Voc & Isc

Controling phosphorous-doping concentration and film thickness

precisely

Controling phosphorous-doping concentration and film thickness

precisely

To improve ampere density

To improve ampere density

To reduce deposition time

To reduce deposition time

To optimize backside antireflection rate

To optimize backside antireflection rate

To improve anti-PID performance

To improve anti-PID performance

SMBB, reducing shading area

SMBB, reducing shading area

To shorten the current transmission path

To shorten the current transmission path

To reduce series resistance and grid silver consumption

To reduce series resistance and grid silver consumption

To improve the tolerance for broken grid line, microcrack and breakage

To improve the tolerance for broken grid line, microcrack and breakage

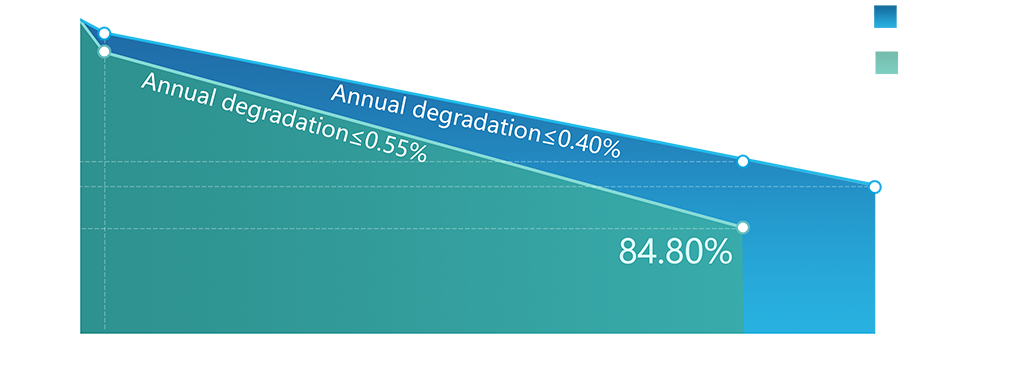

15

years material and process warranty,

30

years performance warranty

30

years material and process warranty,

30

years performance warranty

for some small - sized modules used on residential roofs in certain regions

≤1% first year degradation, ≤0.4% subsequent annual degradation

≥87.40

% of initial output after 30 years

COPYRIGHT © HY SOLAR Co., Ltd. ALL RIGHTS RESERVED 苏ICP备05006512号 苏公网安备 32021102000184号