HY SOLAR Co.,Ltd. is a wholly-owned subsidiary of Hongyuan Green Energy Co., Ltd. Its production base is located in Jiangyin, Wuxi. It has built a downstream base of the photovoltaic industry integrating scientific and technological research and development and intelligent manufacturing under the group.HY SOLAR focuses on the research and development, production and sales of new energy high-efficiency photovoltaic modules, and is committed to providing customers with high-efficiency module products suitable for multiple scenarios. At present, it has formed an invisible production capacity of 26GW.

Total Investment

688Million (USD)

Capacity

26GW

PV Module

Area

3.3w㎡

Wuxi, Jiangsu and Chuzhou, Anhui

This step uses a high energy laser beam generated by a laser scribing machine to irradiate the surface of the solar cell, causing the exposed area to locally melt and vaporize, thereby achieving the purpose of “splitting the cell in one stroke.” HY SOLAR’s production line has introduced non damaging cutting technology. The cut cell edges are smooth and burr free, with no laser damage or heat affected zones. This significantly improves module yield and quality, and cell efficiency can increase by approximately 0.1–0.3% compared to damage prone laser cutting methods.

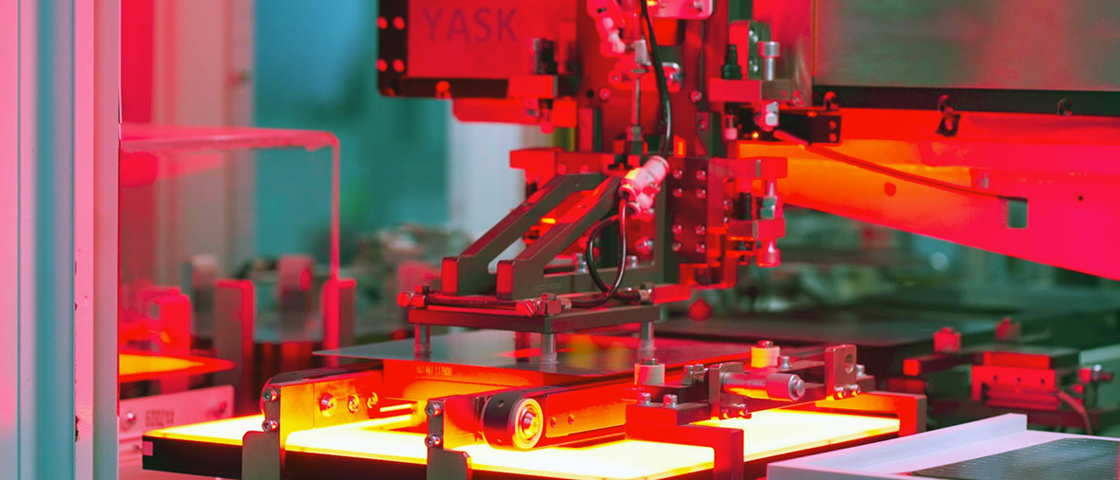

The equipment welds the interconnection ribbon onto the front (positive) main grid of the solar cell. The ribbon is approximately twice the length of the cell’s side. After welding the front of a half cell, the remaining length can be used to weld the back (negative) electrode of the next series connected cell, forming a continuous positive to negative current path. HY SOLAR’s HT series modules adopt the SMBB design, which reduces series resistance and enhances current collection, thereby improving module power output.

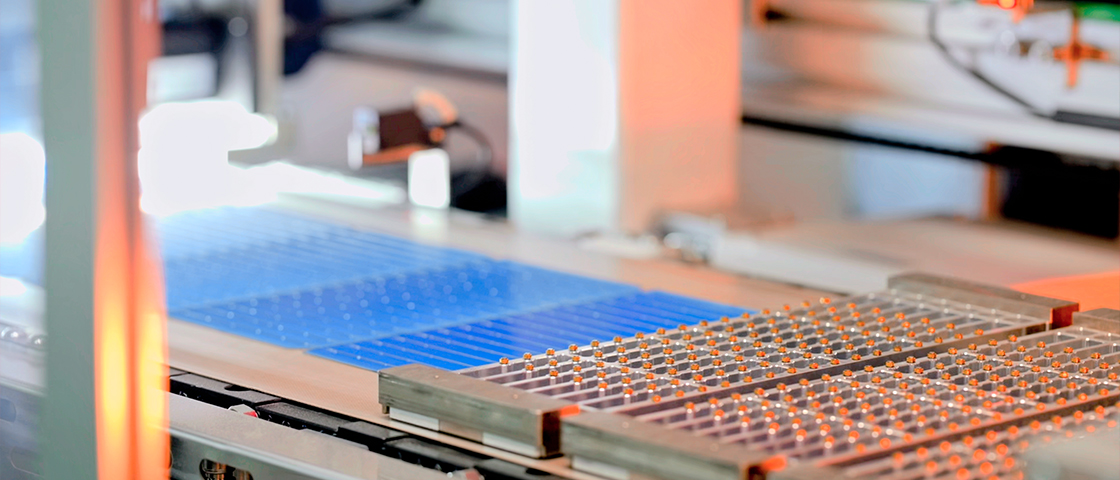

After the cells complete the string welding process, the assembled strings are placed on the glass and EPE film by an intelligent layout machine. In this step, the cells are arranged alternately with positive and negative electrodes. HY SOLAR modules adopt advanced high density packaging technology, reducing the cell to cell spacing from the traditional 2.0 mm to 0.8 mm, enabling close interconnection of the cells. This increases the effective power generating area and improves module efficiency.

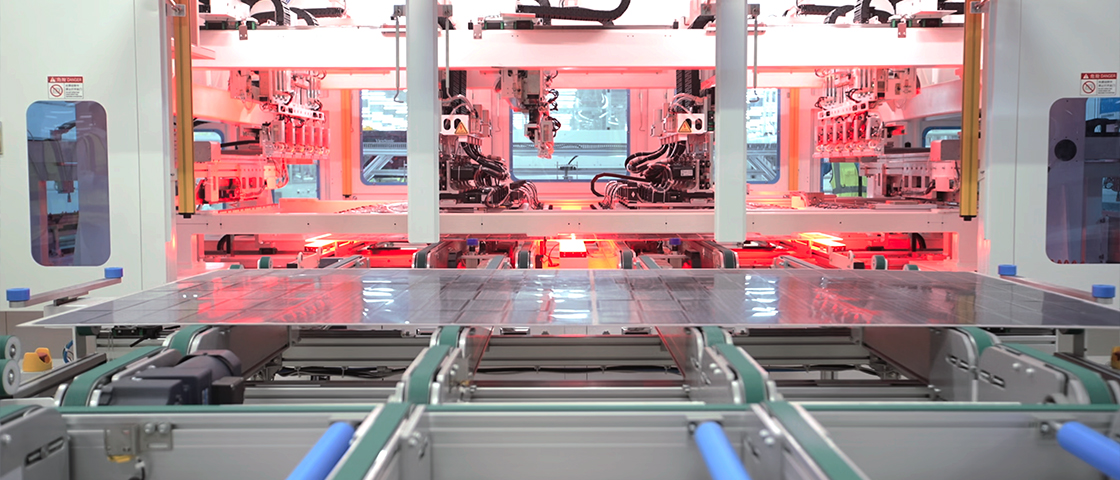

This process uses a fully automatic stacking welding machine to connect the string welded cells together, forming a complete circuit so that the module can deliver power smoothly after installation. HY SOLAR’s stacking welding equipment offers excellent performance, including fast cycle times (≤13 s), wide alignment tolerance (±30 mm, cell positioning accuracy ≤0.3 mm), quick batch changeover (30–50 min), uninterrupted busbar feeding, and defective weld detection. These features ensure the bussing process is both highly efficient and of superior quality.

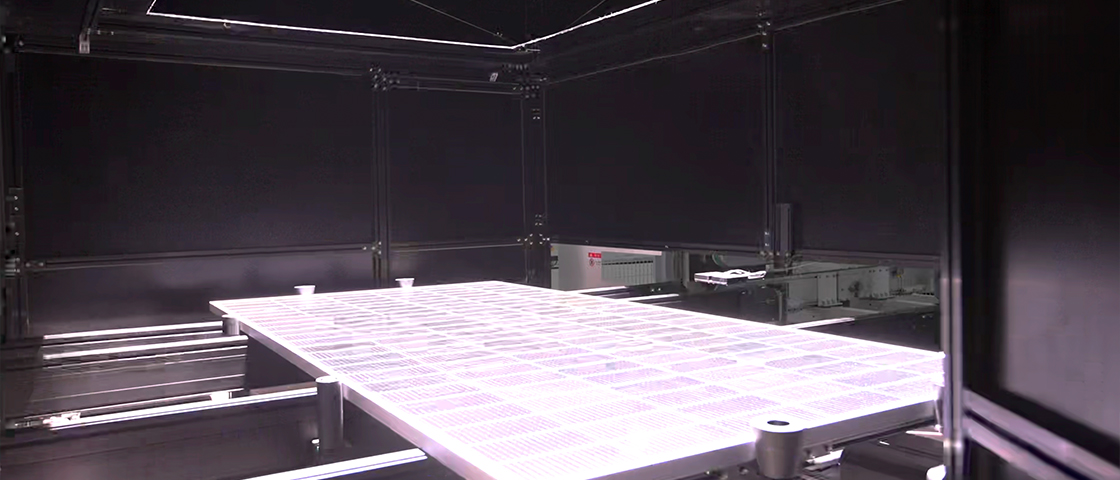

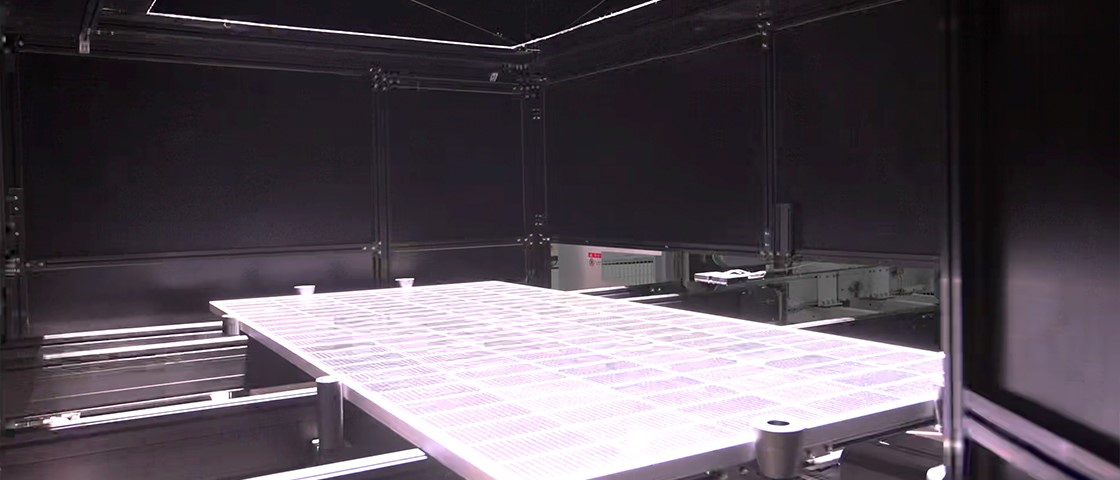

EL, short for Electroluminescence, is also called field induced luminescence. Its purpose is to detect defects in the cells of a module to ensure quality control. HY SOLAR’s production line uses intelligent EL inspection equipment that can simultaneously perform full surface, no blind spot inspections on both sides of the module. This greatly improves inspection efficiency and, when combined with AI capabilities, enables online inspection and intelligent judgment for all products, providing strong assurance of the high performance quality of HY SOLAR modules.

The lamination process is a key step in solar module manufacturing. Its core principle is the combined action of heating, pressing, and vacuuming, which melts and cross links the EVA/EPE film, bonding the module layers (such as tempered glass, solar cells, and backsheet) into a sealed, integrated structure. This protects the internal circuitry and ensures an outdoor service life of up to 30 years. HY SOLAR’s production line uses lamination equipment with three chamber linkage, significantly improving module yield and cleanliness.

This process uses automated equipment to precisely install aluminum alloy frames onto the laminated module, enhancing structural strength and sealing. The core principle involves using pneumatic force and a precision positioning system to achieve automatic glue application, positioning, and fixation of the frame, adaptable to various profiles and size requirements.

HY SOLAR’s production line uses automated junction box welding equipment, which quickly locates both the junction box and the module busbars through a vision system, guiding the welding head for precise connections. The entire operation is fast and efficient. After welding, the intelligent system simultaneously inspects the weld appearance to ensure high quality connections and improve weld pass rates, thereby enhancing the reliability and safety of HY SOLAR modules.

During IV testing, the module’s performance data is collected under simulated sunlight conditions. To ensure standardized comparisons, the industry defines Standard Test Conditions (STC) as follows: AM1.5 spectrum, irradiance of 1000 W/m², and a temperature of 25 °C. HY SOLAR’s production line performs IV testing using the four wire method. The resulting performance data is typically presented on the back of HY SOLAR module datasheets, serving as a key specification of module performance.

COPYRIGHT © HY SOLAR Co., Ltd. ALL RIGHTS RESERVED 苏ICP备05006512号 苏公网安备 32021102000184号